|

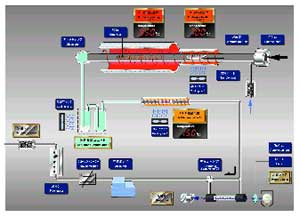

Principle of Operation

All samples are placed on ceramic holders and set into Sample

Changer where all sample introductions will be handled automatically and

sequentially from there. Once transferred into Sample Heating Furnace, sample is

rapidly combusted. The atomized mercury is transferred and trapped (as gold

amalgam), separating it from the other combusted gaseous products. The

amalgamated-mercury is next readily desorbed and mercury vapor is transferred

and detect via Cold Vapor Atomic Absorption at 253.7nm. The analyzed sample is

retrieved and the next sample is introduced. The sequence continues until all

samples positions defined in the Sample Changer are completed.

With an attachment of Impinger Reduction setup, MA-2000

can be configured for Stannous Reduction / Gold Amalgamation / CVAA analysis for

mercury with proven MDL of down to 0.2 ppt or better.

MA-2000 is in compliance with both USEPA 7473 (Mercury in

Solids and Solutions by Thermal Decomposition, Amalgamation and Atomic

Absorption Spectrometry), ASTM D6722-01 (Total Mercury in Coal and Coal

Combustion Residues by Direct Combustion Analysis) and USEPA 1631e (Mercury by

Oxidation, Purge & Trap and Cold Vapor Atomic Florescence Spectrometry or CVAAS).

MA-2000 exhibits significant advantages with its

flexibility and ability to all samples of all matrices and methods (mentioned

above) just under one platform.

Applications

- Environmental (Liquid & Solid Waste and Gaseous)

- Food (Liquid & Solid matrices)

- Biological (Liquid & Solid matrices)

|